Stretch film (stretch wrap, bundling film, stretch wrap film) is a highly stretchable plastic film commonly made from Linear low-density polyethylene (LLDPE) wrapped around items. The elastic recovery keeps the products tightly bound. Also known as stretch wrap, bundling film roll or pallet shrink wrap.

Stretch film is used to wrap products on pallets and secure them to each other and the pallet. Helping to reduce product loss, discourage load tampering, and reduce worker injury.

Two types of stretch film

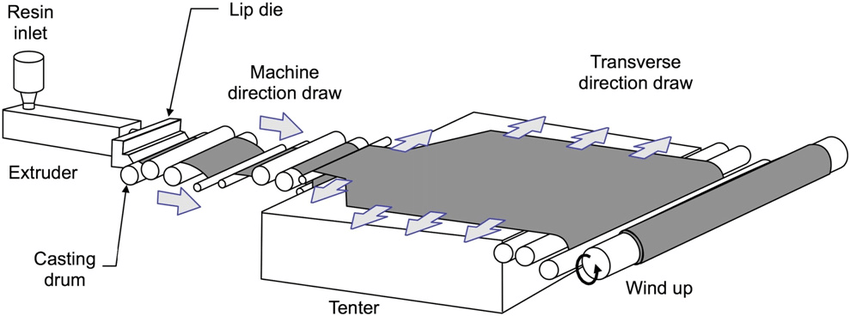

Cast Stretch film: also known as cast film or cast wrap, it is manufactured using a cast extrusion process, which is a continuous process by which a thermoplastic material is melted and extruded through a flat die onto a chill roll, where it is quenched and re-solidified.

Machine & hand grade available.

Advantages of Cast Stretch Film:

- Less expensive than blown stretch film.

- Require less force to stretch.

- Increased tear resistance.

- Unwind quietly from machines.

- Increased clarity allows users to see wrapped products.

- Offers two-sided cling that allows the wrap to stay securely packaged.

Disadvantages of Cast Stretch Film:

- Does not offer the load/holding power blown stretch film provides.

- Has less memory and tear resistance than blown stretch film.

Blown Stretch Wrap: a premium quality film, it is manufactured using the blown extrusion process. This Plastic melt is extruded through an annular slit die, usually vertically, to form a thin-walled tube. Air is introduced from an opening in the center of the die to blow up the film tube like a balloon. On top of the film tube, an air ring blows onto the film to cool it.

Machine & hand grade available.

Advantages of Blown Stretch Wrap

- More robust and more resilient than cast film.

- Offers higher load and stretch capacity.

- has a higher degree of memory once stretched, allowing product loads to stay better secured.

- Higher tear resistance is an advantage when securing loads with sharp edges.

Disadvantages of Blown Stretch Wrap

- Higher cost due to the manufacturing process.

- poor clarity due to crystallization in the manufacturing process.

- Noisy when unwound from rolls.

Since 2006, Packrite has accumulated expertise insight on how to choose the right packaging materials to increase productivity and save cost. Give us a call to discuss your need to avoid wasting thousands of dollars every year. We also have comprehensive range of Stretch Film that meets the diverse needs of our customers.

-

Clear blown hand held stretch film roll 500mm 25um 4 rolls/ctn-sfc10-b$123.20 inc. GST

Clear blown hand held stretch film roll 500mm 25um 4 rolls/ctn-sfc10-b$123.20 inc. GST -

Black cast machine stretch film roll 500mm 20um 1 rolls/ctn-sfb02-c$95.00 inc. GST

Black cast machine stretch film roll 500mm 20um 1 rolls/ctn-sfb02-c$95.00 inc. GST -

Clear cast stretch film-hand roll 500mm 25um 4 rolls/ctn-sfc04-c$84.80 inc. GST

Clear cast stretch film-hand roll 500mm 25um 4 rolls/ctn-sfc04-c$84.80 inc. GST

How to make the right choice of stretch film and save cost?

Choosing black or clear colour?

The black (opaque) stretch film offers a variety of advantages over transparent stretch film:

- Detours pilferage through valuable shipments by concealing products.

- It helps to protect products from UV Rays.

- Prevents damage caused by rain, dew, and dust.

- Outlasts regular transparent stretch film during extended outdoor storage.

- Great for color-coding products.

When to use a UV stretch Film?

Packrite recommends UV Stretch Film if stored outside longer than 60 days.